I am going to try and explain some key items with the starters of our earlier model trucks. First, I have displayed for you 3 specific areas in the electrical system that work together to start your truck when you turn the ignition with a key. Please hang with me during the read, I am far from an electrician and it is not one of my favorite or knowledgeable areas with vehicles.

The information I am posting here was all brought on by an issue I had with my own truck which had starting issues for years. The problem was a weak spark and I chased the problem with money for a long time. I have visited many forums, mechanics, read documents and manuals to fix the problem, but could not figure out where the problem was and why it only acted up at certain times. It can be misdiagnosed very easily and seem fixed after some repairs for a while, but it always returned. It also was very hard on the starter itself causing about 3 replacements and other electrical issues.

I live in an extreme climate area where the weather hits the 100's in summer and can easily drop to below 0 degrees in the winter. This low

voltage starting problem followed the seasons and would rise up in the winter, but would lay pretty much dormant in the summer. This problem does not affect all trucks in the same way either. Some may never notice a low

voltage starting problem if they live in a warmer climate. So with this said, letís move on by discussing the starter and the "S" and "R" terminals on the starter that some of our trucks might have on them.

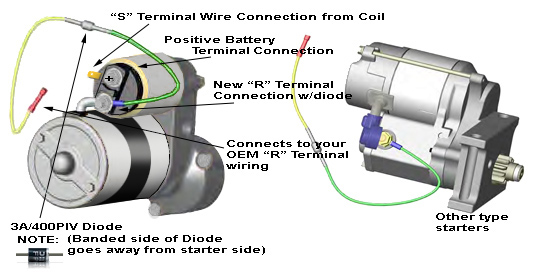

Our starters on earlier trucks came in 2 versions, Which one should we be using?

They all come with a piggy back solenoid with 2 large post connectors, one for the positive battery connection and the other has a large gauge wire going to it, coming from within the starter.

Now,

Version 1 starter has an "S" connection and also a single wire connection coming off solenoid which we call an "R" connection. This "R" connection is used to bypass a Ballast Resistor during the starting period only. It makes sure there is a full 12volts and proper amperage being applied to the system during the importantly starting procedure. The "R" connection was common on the old pointís distributor type model vehicles if you can remember those days. Not to be confused with a inhibitor connection that will not start an automatic transmission vehicle in gear or the clutch safety switch connection.

Now,

Version 2 starter only has the "S" connection with no "R" wire connector coming off it. Both types of starters will work on a vehicle without ballast and can even work on vehicles with ballast. If you have ballast on your coil, you can almost guarantee you need the starter that has both the "S" & "R" connectors.

In early original wiring harnesses, the "R" circuit was a ballast resistor bypass. This terminal is no connection when the starter is at rest, and is +12VDC while cranking.

This circuit provided +12VDC to the ignition coil during cranking for easier engine starting. Cars that do not have a ballast resistor (i.e. HEI, MSD, or other aftermarket ignition systems) should not need this connection. In most cases, this wire can be eliminated. If the engine has no ignition during cranking, then the wiring of the coil is going to require an "R" terminal signal. There is a lot of debate on how and when and what the "R" terminal is for and if it is needed. Believe me, I have read many forum arguments that were debating amongst themselves on this subject and everyone felt they were right. All I know is, this is where cold weather affected my vehicle during starting. Cold weather causes some difficulty for vehicles to be able to start up quickly if there is not a full 12v going to the coil. There are many factors besides cold weather that causes starting problems without a full 12v supply, like a vehicle out of tune, an aged engine, wiring becoming old and increased resistance, etc. Mine just happen to be the cold weather that hit the hardest, in addition to aged engine and some older wiring. The main reason though was I switched to a starter without a "R" terminal and taped up the OEM "R" wire and forgot all about it, until recently.

S=Start or solenoid, I think start

R=relay provides voltage only when energized.

See, when a starter engages it drops the battery

voltage to approx. 10.5 - 11 volts (batteries of 30 years ago were nowhere close to the technology of today and may have even dropped lower). Going through the resistor wire the spark would be too weak to fire the plugs well enough to start under some conditions, like cold winter weather. Sending the available battery

voltage to the coil while starting boosted the output of the coil allowing for easier starting. A related topic there is two windings in the solenoid the "Pull in" and the "Hold in" windings. The Pull in is wired between the S and the big starter terminal. Current would flow until the solenoid engages. The hold in winding goes between S and ground and always draws current. Therefore the solenoid current should be 15A when first energized and should drop down to 5a once engaged.

IMPORTANT

The starter circuit pulls a lot of amperage, up to 500 amps depending on the

starter, the engine load, and battery condition. This kind of amperage stresses all of the components in the starter circuit, including the battery, battery terminals, the battery disconnect switch, the cables including the ground path, and any remote solenoids. Problems with these components are hard to find because they appear fine at rest or under a light load, but generate high resistance under heavy amperage draws. The result will be low

voltage to the starter during cranking, resulting in heavier amperage draw and increased internal heat in the starter. Over time, this will cause starter failure.

Voltage measured at the starter during cranking should always be above 9.5VDC.

OK, with all this said...You walk outside and find out you have ballast resistor sitting on or near your coil. You also find out you have a starter without the "R" connection that bypasses the ballast during starting. Well, consider yourself lucky if you have never noticed any starting problems like I had for so many years. There is a very affordable way to correct an issue of having a Non "R" terminal starter with a ballast resistor installed and get the full benefit and

voltage during engine starts.

This is the easiest way it is done...

To accomplish this, connect a

3A/400PIV diode in line with the MOTOR SIDE of the solenoid. (Note: This is the terminal on the solenoid which has the cable from inside the starter motor connected to it. It is opposite the BATTERY terminal on the solenoid. The cathode or banded end of the diode goes away from the starter. This allows current to go from the starter to the coil and yet not from the coil to the starter.)

You can make this part in about 5 minutes using some wire, connectors and going to Radio Shack and purchasing a

3A/400PIV diode , total cost about $5. Or

Purchase 3A/400PIV diode kit from (

Powermaster part# 600 )

This is yet another way to correct this problem...

Install a relay using these connections,

-connect 30 to power (like the battery lug on solenoid),

-85 to ground

-86 to your starter wire

-87 to the + side of coil

-14 gauge will be fine.

Yet another way, but more expensive also...

Remove your ballast resistor and install a High output Mallory or Accell ignition system, Coil.

Starter Cable Testing

First of all if the car is a manual tranny put it in neutral and set the parking brake firmly.

To test the cabling you would want to jump from the battery to the incoming lead on the solenoid, try the key. If there still is no reaction use a screwdriver to jump from the incoming terminal on the Solenoid to the small lug on the solenoid. If there is a reaction there is a fault with the either a fuse, the ignition itself or the ignition wiring. (Or clutch safety switch if manual tranny & not it park gear if automatic.) If there is still no reaction, remove the starter from the vehicle including the solenoid and take it to AutoZone or O'reillyís to have it tested for free.

Bookmarks